01

/01

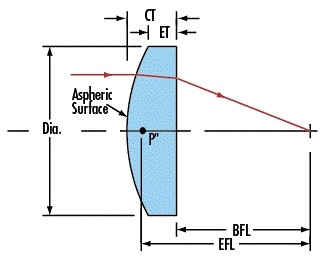

The aspheric glass lens is formed by pressing the ball with a precision mold after softening it at high temperature. A single-element design helps reduce the number of lenses in a multi-lens optical assembly.

Attribute:

Materials: Low melting point optical glass

Include: BK7, fused silica, zinc selenide ZnSe, zinc sulfide ZnS, germanium Ge, silicon Si, calcium fluoride GaF2, magnesium fluoride MgF2, sapphire Al2O3, optical glass, etc..

Design wavelength: 635nm, 520nm, 786nm, 530nm, 800nm, 655nm (can be customized according to user needs)

Focal length tolerance: ±1%

Outline tolerance: +0.00/-0.10mm

Thickness tolerance: ±0.2mm

Surface accuracy: PV<0.2μm after optimization

Finish: 40-20

Eccentricity: <90°

Coating: (can be coated according to user needs)

Introduction to Aspheric Lenses:

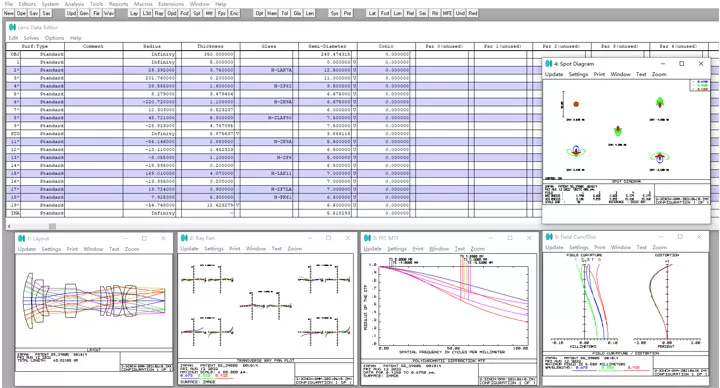

The aspheric glass lens is formed by pressing the ball with a precision mold after softening it at high temperature. A single-element design helps reduce the number of lenses in a multi-lens optical assembly. In other words, unlike conventional lenses with spherical shape, aspheric lenses have a more complex surface that continuously changes in curvature l gradually from the center of the lens to the edge of the lens. Therefore, in addition to the inherent good refractive index, dispersion characteristics and environmental adaptability of glass lenses, aspheric glass lenses can better correct distortion and equiaxial aberrations, thereby reducing the number of optical components used and simplifying the system structure. Improve the imaging quality of the optical system.

Advantages:

The advantages of aspheric lens are: improving the imaging quality of the system, simplifying the complexity of the structure, and improving the reliability of the system.

One of the most significant advantages is the correction of spherical aberration caused by spherical lenses in collimating and focusing systems. By adjusting the surface constant and aspheric coefficient, the aspheric lens can eliminate the spherical aberration to the greatest extent. Aspheric lenses (light converging to the same point, providing optical quality) essentially eliminates the spherical aberration (light converging to different points, resulting in blurry images) produced by spherical lenses. Incorporating aspheric surfaces into applications such as focusing the output of a laser diode can not only reduce overall cost, but can also outperform components designed using traditional spherical optical lenses.

Production Capacity Sheet:

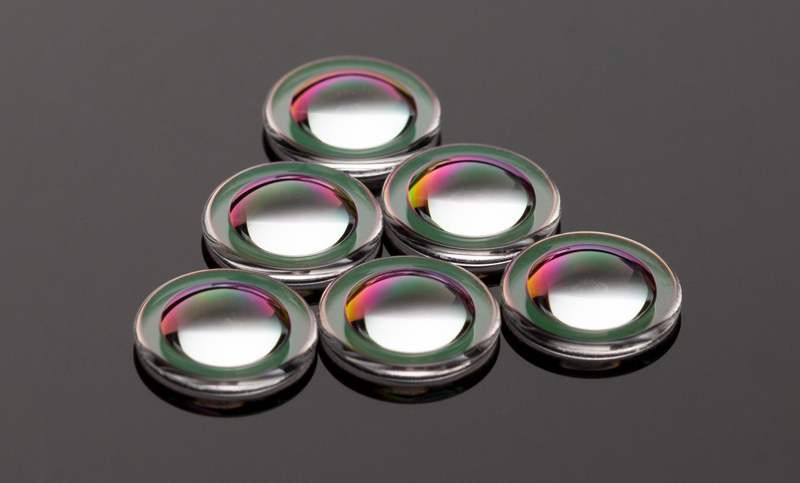

Our company can process various specifications of aspherical lenses according to the different needs of customers. The processing range of aspherical lenses is Ф2-Ф35mm.

| Guaranteed Precision(μ) | Diameter | φ2—φ10mm | φ10—φ20mm | φ20—φ30mm |

| Fig-PV | 0.5μm | 1μm | 1.5μm | |

| Acc-PV | 0.2μm | 0.3μm | 0.3μm | |

| AS | 0.08μm | 0.1μm | 0.1μm | |

| Decenter | 4μm | 5μm | 6μm |

Monthly Capacity Aspheric lenses: 1,200,000 pcs

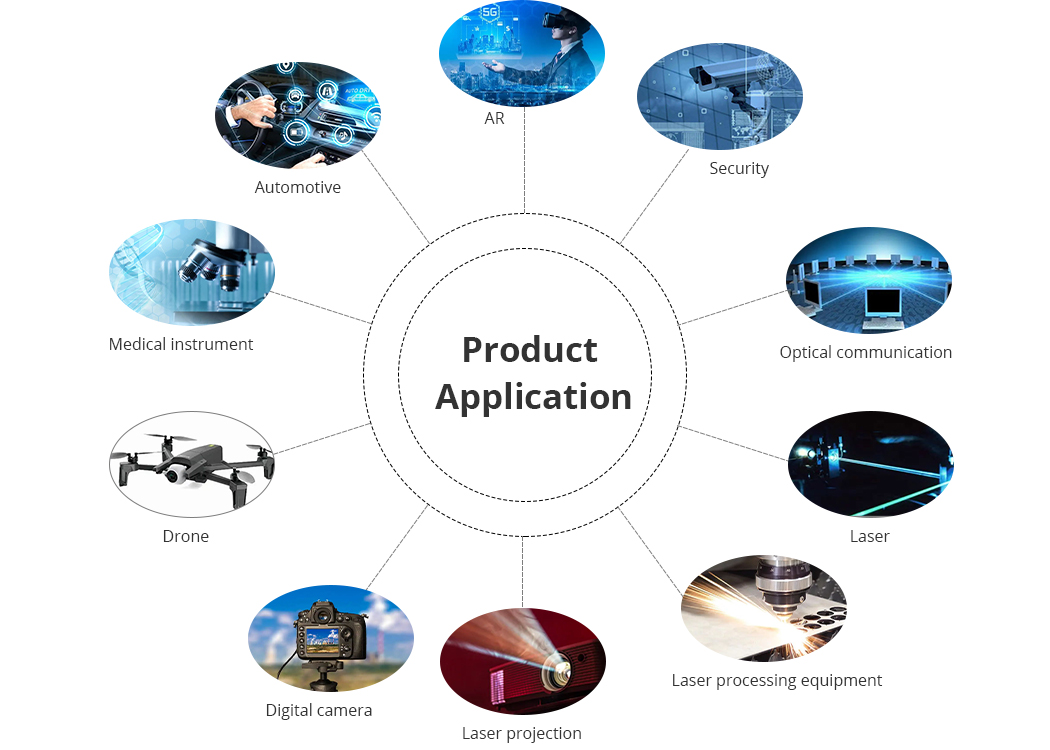

Application:

Because spherical lenses have great advantages in improving system imaging quality, simplifying structural complexity, and improving system reliability, aspheric lenses are widely used in various optical systems. Applications: digital cameras, automotive, security, laser projection, optical communications, medical, drones, AR, etc.

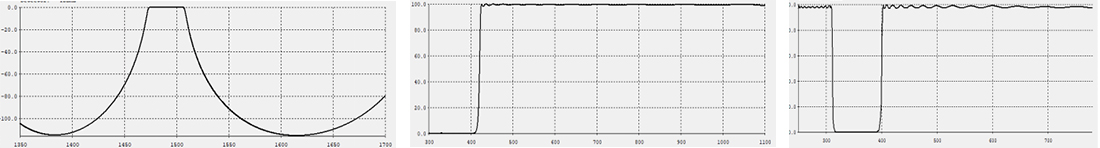

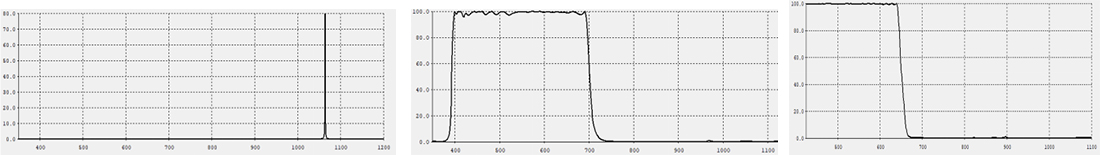

Standard Optical Coating:

We provides high-quality coating services. Our company has successively introduced several Optorun coating machines and SHINCRON sputtering coating machines, with standard &high quality coating technical capabilities. We can customize the coating according to the individual needs of customers, and provide free design and testing

| Coating series | |||||

| Antireflection coating | 400nm-1000nm, R<=0.5% | ||||

| High reverse coating | 420nm-720nm, R>=98% | ||||

| Metal coating | gold coating, silver coating, aluminum coating etc | ||||

| Spectro coating | neutral spectro coating, PBS coating, dichroscope coating etc. | ||||

| Filter coating | long wave pass filter, short wave pass filter, bandpass filter, narrow bandpass filter etc | ||||

| Functional coating | waterproof coating, anti-fouling coating、UV-IR-CUT、super hard coating, EMS anti-static coating, ITO conductive coating etc | ||||

Why Choose Us?

Advanced technology research and development capabilities

The company has continuously introduced outstanding talents at home and abroad, and has a research and development team composed of advanced technical talents such as doctoral and master students and senior professional engineers. Independent research and development, with a total of more than 40 patents for technical inventions and utility models related to optical lenses, lenses and instruments.

With strong R&D capabilities, advanced production equipment and strict quality control system, our lens series has expanded to a wide range of industrial-grade products, covering 1/7.5", 1/4", 1/3", 1/1.8", 2/3” to 1.2” and even larger, there are corresponding solutions to support.

The company's lens and lens products cover the fields of security, machine vision, medical, automotive, sights, smart home and sports cameras. According to customer needs, we can provide ODM services and exclusive customized research and development.

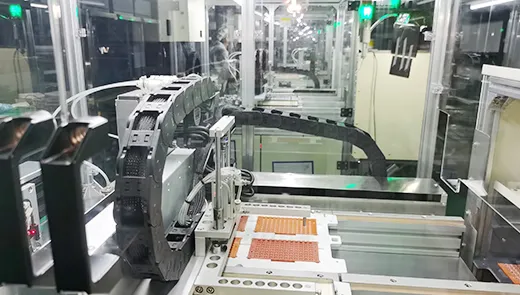

Excellent manufacturing capacity

HR Optoelectronics always adheres to high-standard product quality requirements to provide customers with comprehensive solutions for optical products, pays attention to product quality, and is fully equipped with precision testing instruments and high-end production equipment. Lens, lens and instrument design, research and development, processing, and assembly have a complete production chain and sufficient production capacity, and each link is checked layer by layer.

The imported new Cologne sputtering coating machine is used, which can effectively improve the accuracy of the lens and the uniformity of the transmittance of the film layer; on the detection instrument, the eccentricity detection, surface detection, and coating curve detection are all imported or domestically produced. , to ensure the validity of inspection data and product quality and product yield, thereby improving production efficiency. The complete facilities and the complete personnel provide a strong guarantee for our manufacturing.

Strict inspection process

The company has passed the international quality system certification ISO 9001:2015 and the automotive industry quality management system certification IATF 16949, and has established a rigorous, complete and high-standard quality control system. From procurement to production to after-sales quality control, there is a clear and definite standard system. The company follows the concept of customer orientation and strict process control, and runs quality control procedures throughout the entire life cycle of products to ensure that from raw materials to after-sales service. quality. The company's internal management takes 5S as the standard, and the quality control of product production takes 6sigma as the goal, striving to win the support of customers with the most stable quality.

Perfect supporting services

Our departments have a clear division of labor, production and office work are strictly implemented according to 5S standard. Have perfect pre-sales and after-sales service. With advanced technology R&D capability, high-quality manufacturing capability and strict inspection process, a strong manufacturing, quality control and operation service system has been built, which provides a strong guarantee for the sustained and high-speed development of enterprises.

Workshop equipment

We are looking forward to establishing long-term cooperative relations with customers around the world on the basis of trust and mutual benefit. Please feel free to contact us for further information. We sincerely welcome you to our factory.

Copyright © Jiangxi High-Resolution Optoelectronic Co., Ltd. All Rights Reserved | Sitemap