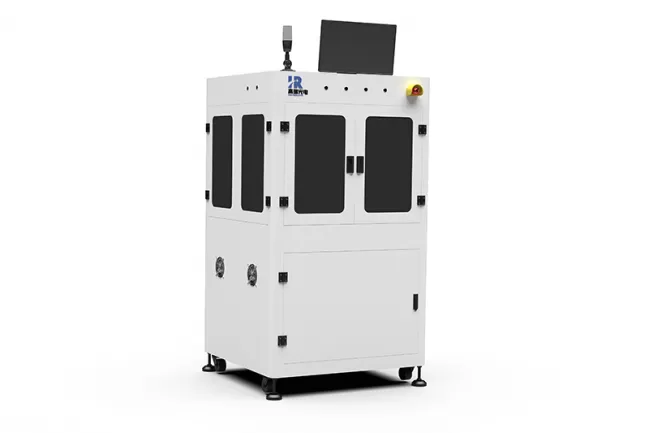

01

/01

Function Brief :

The optical non-contact detection method is adopted, Cooperating with intelligent control and analysis software, Enabling non-destructive measurement of the center thickness of different types of optical lenses.

Workflow:

The lens to be tested is manually loaded through the material tray, The robot automatically draws the lens to the measuring position, Lens thickness is measured by means of an optical non-contact sensor, Quantity results are automatically classified according to pre-set values by the customer, Such as A, B, and NG categories, The robot then places them into different reels.

Product Features:

1. It adopts an optical non-contact measurement method, and there is no damage to the lens surface;

2. The detection speed is fast, the measurement results are accurate and stable;

3. the software supports path planning for a wide range of shaped Ulti-level classification of measurement results;

4. Real-time display of reel status, automatic statistical data analysis, and report generation;

5. Reserved MES system interface to facilitate intelligent monitoring of work information;

6. The equipment runs stably, operates simply and quickly, and saves labor costs.

Technical Specifications:

| Device model | JHD-XB-01 | ||||||

| Detection mode | Contactless | ||||||

| Loading and unloading method | Reels | ||||||

| Detection accuracy | ±1.5μm | ||||||

| UPH | 720 | ||||||

| Lens specifications | Ф5~50㎜,thickness <9mm | ||||||

| Device weight | 450㎏ | ||||||

| Overall machine size | 970mm(L) * 960mm(W) * 1750mm(H) | ||||||

| Operating voltage | AC220V/50HZ | ||||||

| Working air pressure | 0.5MPa~0.7MPa | ||||||

| Rated power | 1.5 KW | ||||||

| Ambient temperature | 10-40℃ | ||||||

| Ambient humidity | ≤80% No condensation | ||||||

Why Choose Us?

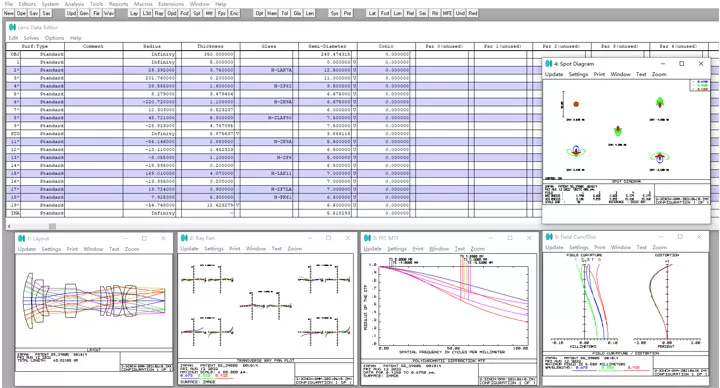

Advanced technology research and development capabilities

The company has continuously introduced outstanding talents at home and abroad, and has a research and development team composed of advanced technical talents such as doctoral and master students and senior professional engineers. Independent research and development, with a total of more than 40 patents for technical inventions and utility models related to optical lenses, lenses and instruments.

With strong R&D capabilities, advanced production equipment and strict quality control system, our lens series has expanded to a wide range of industrial-grade products, covering 1/7.5", 1/4", 1/3", 1/1.8", 2/3” to 1.2” and even larger, there are corresponding solutions to support.

The company's lens and lens products cover the fields of security, machine vision, medical, automotive, sights, smart home and sports cameras. According to customer needs, we can provide ODM services and exclusive customized research and development.

Excellent manufacturing capacity

HR Optoelectronics always adheres to high-standard product quality requirements to provide customers with comprehensive solutions for optical products, pays attention to product quality, and is fully equipped with precision testing instruments and high-end production equipment. Lens, lens and instrument design, research and development, processing, and assembly have a complete production chain and sufficient production capacity, and each link is checked layer by layer.

The imported new Cologne sputtering coating machine is used, which can effectively improve the accuracy of the lens and the uniformity of the transmittance of the film layer; on the detection instrument, the eccentricity detection, surface detection, and coating curve detection are all imported or domestically produced. , to ensure the validity of inspection data and product quality and product yield, thereby improving production efficiency. The complete facilities and the complete personnel provide a strong guarantee for our manufacturing.

Strict inspection process

The company has passed the international quality system certification ISO 9001:2015 and the automotive industry quality management system certification IATF 16949, and has established a rigorous, complete and high-standard quality control system. From procurement to production to after-sales quality control, there is a clear and definite standard system. The company follows the concept of customer orientation and strict process control, and runs quality control procedures throughout the entire life cycle of products to ensure that from raw materials to after-sales service. quality. The company's internal management takes 5S as the standard, and the quality control of product production takes 6sigma as the goal, striving to win the support of customers with the most stable quality.

Perfect supporting services

Our departments have a clear division of labor, production and office work are strictly implemented according to 5S standard. Have perfect pre-sales and after-sales service. With advanced technology R&D capability, high-quality manufacturing capability and strict inspection process, a strong manufacturing, quality control and operation service system has been built, which provides a strong guarantee for the sustained and high-speed development of enterprises.

We are looking forward to establishing long-term cooperative relations with customers around the world on the basis of trust and mutual benefit. Please feel free to contact us for further information. We sincerely welcome you to our factory.

Copyright © Jiangxi High-Resolution Optoelectronic Co., Ltd. All Rights Reserved | Sitemap