01

/01

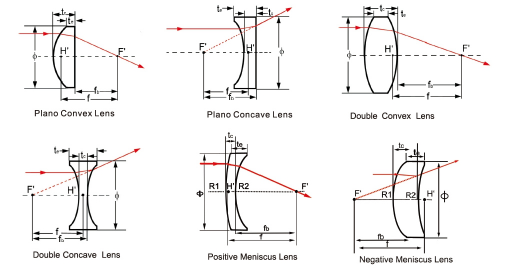

A plano concave lens is a lens that is flat on the one side and concave on the other. Plano concave lenses converge parallel light, correct the deflected light and convert point light sources into parallel light.

Attribute:

Main materials: all kinds of high-quality environmental protection optical glass. Contains: optical glass H-K9, H-BAK7, quartz, fused silica, sapphire, etc.

Focal length: ±5mm~1000mm±2%

Thickness tolerance: ±0.2mm

Size: 6mm-300mm

Surface type: λ/10~λ/2

Surface quality: 10/5~80/50

Eccentricity: <3arcmin

Effective aperture: >90%

Chamfer: <0.2*4.5°

Coating: according to customer requirements

Introduction of Plano-Concave Lenses

A plano concave lens is a lens that is flat on the one side and concave on the other. Plano concave lenses converge parallel light, correct the deflected light and convert point light sources into parallel light. When light enters from the concave surface of the plano concave lens, the light will converge to a point on the concave surface. When a point light source enters from the plane of the plano concave lens, the light will be turned into a parallel beam. The focal length of a plano concave lens can vary depending on wavelength. Plano concave lenses can be used in transmitters, detectors and lasers.

Spherical lens features

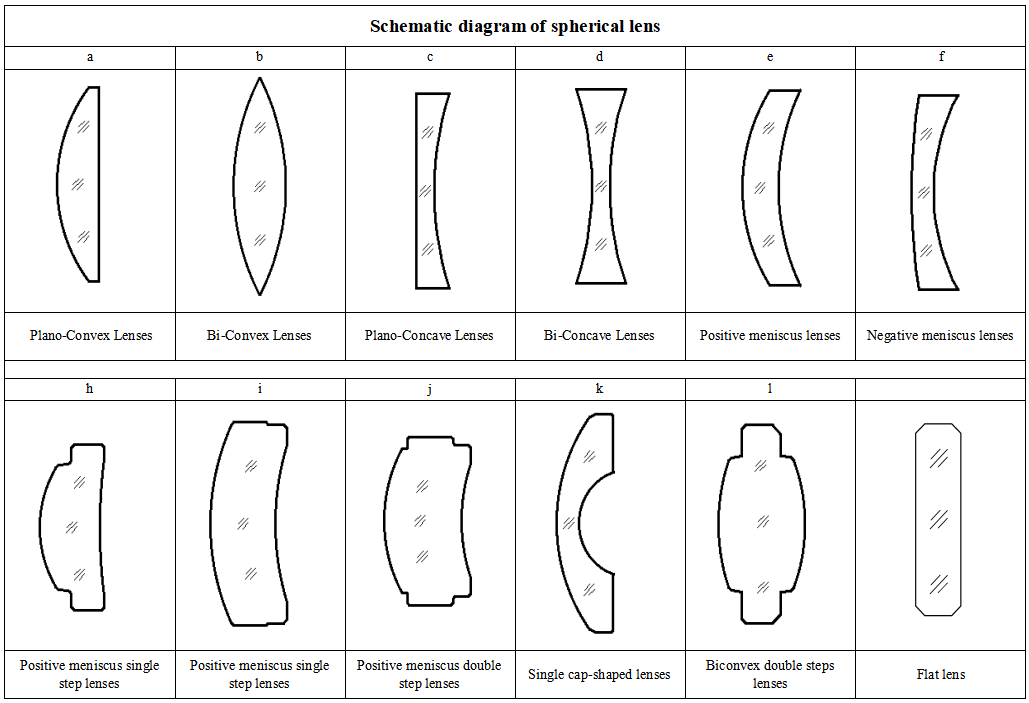

Spherical lens processing types

Plano-convex lenses, double-convex lenses, plano-concave lenses, double-concave lenses, positive meniscus lenses, negative meniscus lenses, flat lenses, single-cap lenses, double-convex double-step lenses,

Plano-concave lens scatters parallel light outward. The focal length of the plano-concave lens is negative, and the spherical aberration is also negative, which can be used to correct the aberration, spherical aberration, coma, and distortion of other lenses. Similar to a plano-concave mirror, the sides generally face the far object surface or infinity. The plano-concave lenses produced by Dingxinsheng Optical are usually made of K9 glass, and their anti-reflection coating is aimed at the wavelength range of 400-700 nanometers. There are also UV quartz as the base material for processing. When UV quartz is used as the base material, it has good transmittance and low thermal expansion coefficient in the ultraviolet region, and can be coated with UV AR film for use in special circumstances.

Production Capacity Sheet

| Category (Diameter) | Thickness Tolerance | Surface Precision | Surface | Eccentricity | Abrasion Degree |

| φ2~φ3.5 | ±0.015 | 0.3 | 10xMicroscopic test: the center is flawless, and the edge is 20-10 | 120″ | 40-300 |

| φ3.5~φ10 | ±0.015 | 0.3 | 45″ | 40-488 | |

| φ10~φ25 | ±0.02 | 0.3 | 15-20 | 30″ | 40-488 |

| φ25~φ40 | ±0.02 | 0.3 | .20-10 | 30″ | 40-488 |

| φ40~φ55 | ±0.02 | 0.5 | 40-20 | 30″ | 40-488 |

| φ55~φ80 | ±0.02 | 0.5 | 40-20 | 30″ | 40-300 |

| φ80~φ150 | ±0.03 | 1.0 | 40-20 | 30″ | 40-300 |

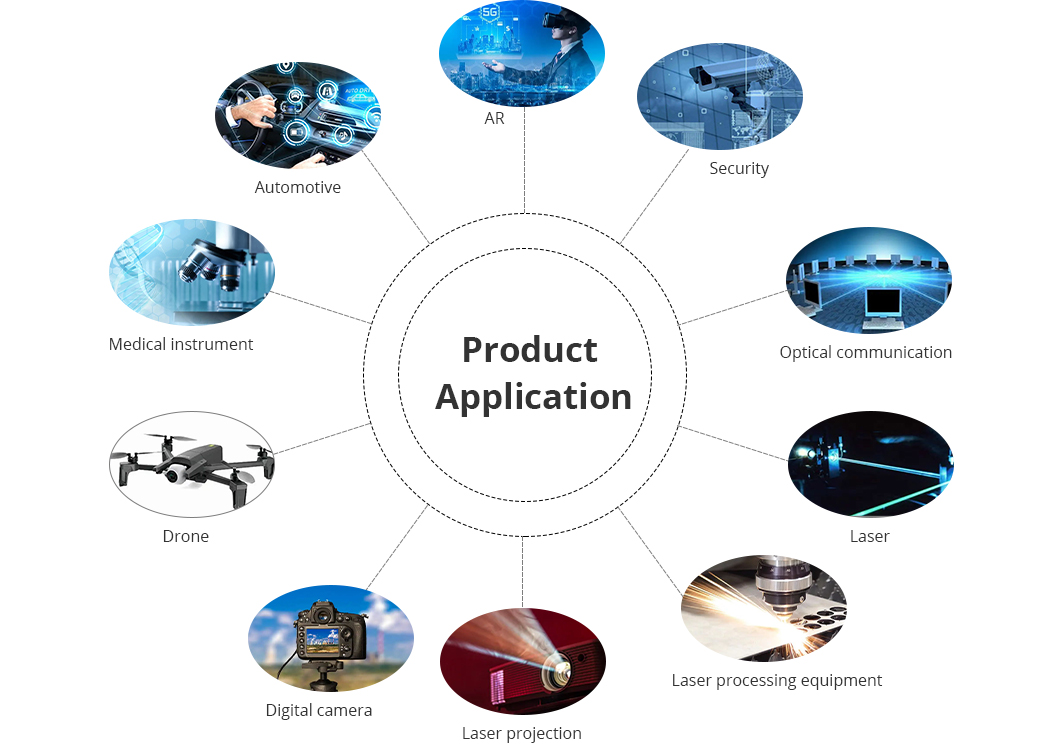

Application

Glass lenses have a wide distribution of refractive index and dispersion, and have good adaptability to temperature and environment. They are widely used in high-end optical lenses, such as digital cameras, security, automotive, optical communications, laser projection, medical, unmanned machine, AR, etc.

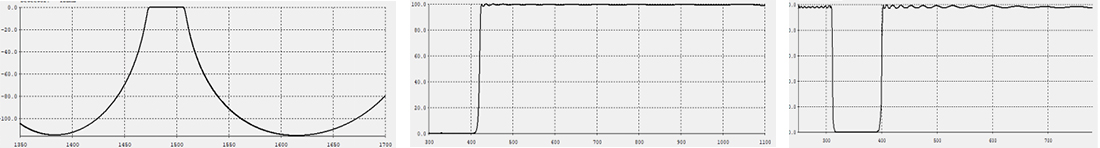

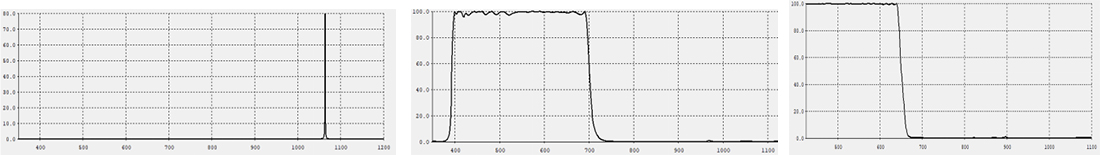

Standard Optical Coating

We provides high-quality coating services. Our company has successively introduced several Optorun coating machines and SHINCRON sputtering coating machines, with standard &high quality coating technical capabilities. We can customize the coating according to the individual needs of customers, and provide free design and testing

| Coating series | |||||

| Antireflection coating | 400nm-1000nm, R<=0.5% | ||||

| High reverse coating | 420nm-720nm, R>=98% | ||||

| Metal coating | gold coating, silver coating, aluminum coating etc | ||||

| Spectro coating | neutral spectro coating, PBS coating, dichroscope coating etc. | ||||

| Filter coating | long wave pass filter, short wave pass filter, bandpass filter, narrow bandpass filter etc | ||||

| Functional coating | waterproof coating, anti-fouling coating、UV-IR-CUT、super hard coating, EMS anti-static coating, ITO conductive coating etc | ||||

Why Choose Us?

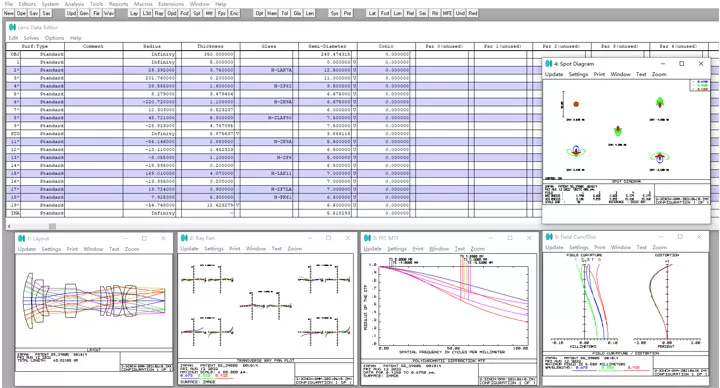

Advanced technology research and development capabilities

The company has continuously introduced outstanding talents at home and abroad, and has a research and development team composed of advanced technical talents such as doctoral and master students and senior professional engineers. Independent research and development, with a total of more than 40 patents for technical inventions and utility models related to optical lenses, lenses and instruments.

With strong R&D capabilities, advanced production equipment and strict quality control system, our lens series has expanded to a wide range of industrial-grade products, covering 1/7.5", 1/4", 1/3", 1/1.8", 2/3” to 1.2” and even larger, there are corresponding solutions to support.

The company's lens and lens products cover the fields of security, machine vision, medical, automotive, sights, smart home and sports cameras. According to customer needs, we can provide ODM services and exclusive customized research and development.

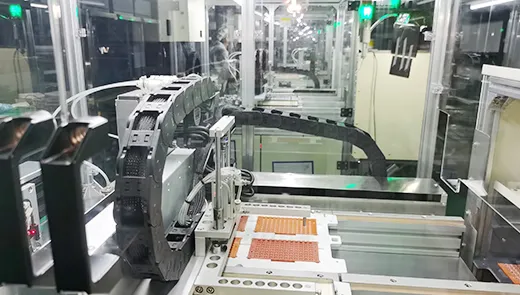

Excellent manufacturing capacity

HR Optoelectronics always adheres to high-standard product quality requirements to provide customers with comprehensive solutions for optical products, pays attention to product quality, and is fully equipped with precision testing instruments and high-end production equipment. Lens, lens and instrument design, research and development, processing, and assembly have a complete production chain and sufficient production capacity, and each link is checked layer by layer.

The imported new Cologne sputtering coating machine is used, which can effectively improve the accuracy of the lens and the uniformity of the transmittance of the film layer; on the detection instrument, the eccentricity detection, surface detection, and coating curve detection are all imported or domestically produced. , to ensure the validity of inspection data and product quality and product yield, thereby improving production efficiency. The complete facilities and the complete personnel provide a strong guarantee for our manufacturing.

Strict inspection process

The company has passed the international quality system certification ISO 9001:2015 and the automotive industry quality management system certification IATF 16949, and has established a rigorous, complete and high-standard quality control system. From procurement to production to after-sales quality control, there is a clear and definite standard system. The company follows the concept of customer orientation and strict process control, and runs quality control procedures throughout the entire life cycle of products to ensure that from raw materials to after-sales service. quality. The company's internal management takes 5S as the standard, and the quality control of product production takes 6sigma as the goal, striving to win the support of customers with the most stable quality.

Perfect supporting services

Our departments have a clear division of labor, production and office work are strictly implemented according to 5S standard. Have perfect pre-sales and after-sales service. With advanced technology R&D capability, high-quality manufacturing capability and strict inspection process, a strong manufacturing, quality control and operation service system has been built, which provides a strong guarantee for the sustained and high-speed development of enterprises.

Workshop equipment

We are looking forward to establishing long-term cooperative relations with customers around the world on the basis of trust and mutual benefit. Please feel free to contact us for further information. We sincerely welcome you to our factory.

Copyright © Jiangxi High-Resolution Optoelectronic Co., Ltd. All Rights Reserved | Sitemap